We can offer a bespoke design service according to our customer needs, whether you require an authentic product or a new design we can provide both.

Our Heritage has allowed us to retain all of the drawings, microfilms and instruments build information for car instrumentation dating as far back as 1956

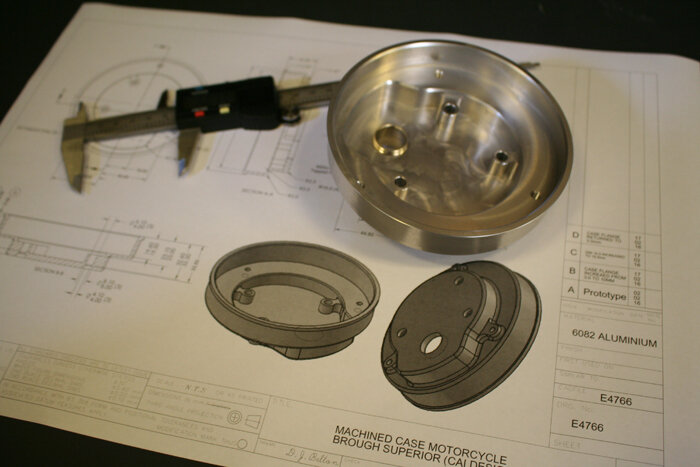

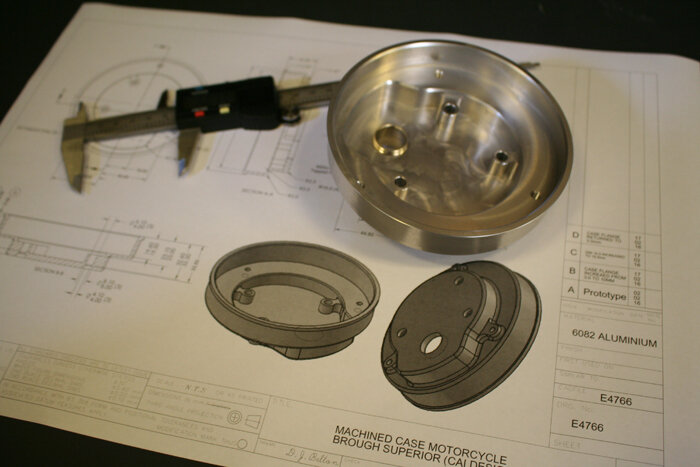

We have invested in the latest Solidworks software so that our drawings can be used by our suppliers to set their manufacturing equipment quickly and efficiently.

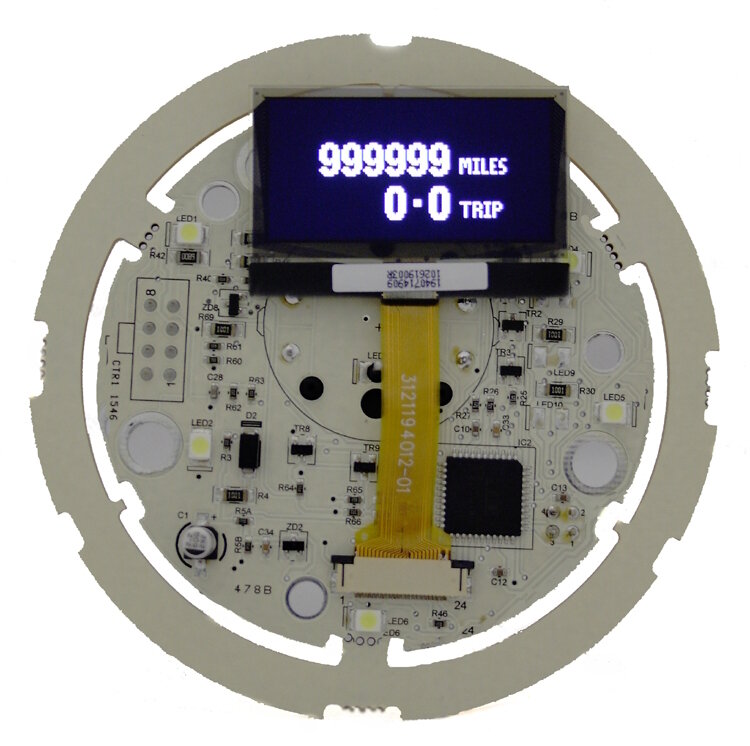

Our highly experienced programming team are continually improving and expanding the feature set of all our processor driven gauges. This includes better interference suppression, improved accuracy, wider sender and sensor selection for all our minor gauges.

New display technologies are also being introduced, with a new range of OLED displays, allowing further customisation of each gauge including the choice of multiple gauges in one package, user selection of minor gauge senders and sensors, and a clear graphical representation of information such as fuel level.

Our design capabilities encompasses a programming team that can be called upon to customise the gauges for a particular make and model of vehicle with bespoke graphics and feature sets.

Continual research into new and more powerful processors and human interface technology is also being expedited. These will allow the use of larger and clearer display areas, touch technologies and environmentally hardened devices for use, for instance, on motorcycles and marine applications.

On the systems side, interfacing with NMEA 2000 and the use of GPS systems is also being introduced.

We have the following capabilities in Electronic Design and Manufacture

At CAI we design, develop and print all of our dial faces, we employ older technologies such as pad and screen printing and have recently invested heavily in new technologies, allowing us to improve quality, print finer detail at the same time reducing set up times.

We have also invested in ultrasonic cleaning technology which contributes to an improved and consistent paint finish

In addition to the SMITHS Classic, Cobra, International and Telemetrix ranges, we are able to tailor our manufacturing to offer bespoke designs. The same rugged and proven instruments can be customised to suit your styling requirements, and can be adapted for automotive, motorcycle or marine applications.

Whether you require dial colours to complement your interior trim or graphics to reinforce your company image, or both, we can offer a solution.

Some of our prestigious project customers that have taken advantage of this bespoke option include Singer Vehicle Design, Caterham Cars, Morgan Motor Company. motorcycle manufacturer Langen Motorcycles ,and marine customer Seven Seas Yachts. Your corporate colours, your company logo, both can be incorporated on your speedometer, tachometer and monitoring gauges. We have even designed a set of gauges for a custom aviation project!

Instruments, switches, warning lights, and wiring harness can all be incorporated.

Some of our bespoke prestigious project customers have included Singer Vehicle Design, Langen Motorcycles and Morgan Motor Company.

Examples of some of our most recognised custom instrument designs can be viewed on our automotive, motorcycle and marine project pages.

For further information on our bespoke gauge designs or to enquire about our standard Smiths range of gauges please contact us